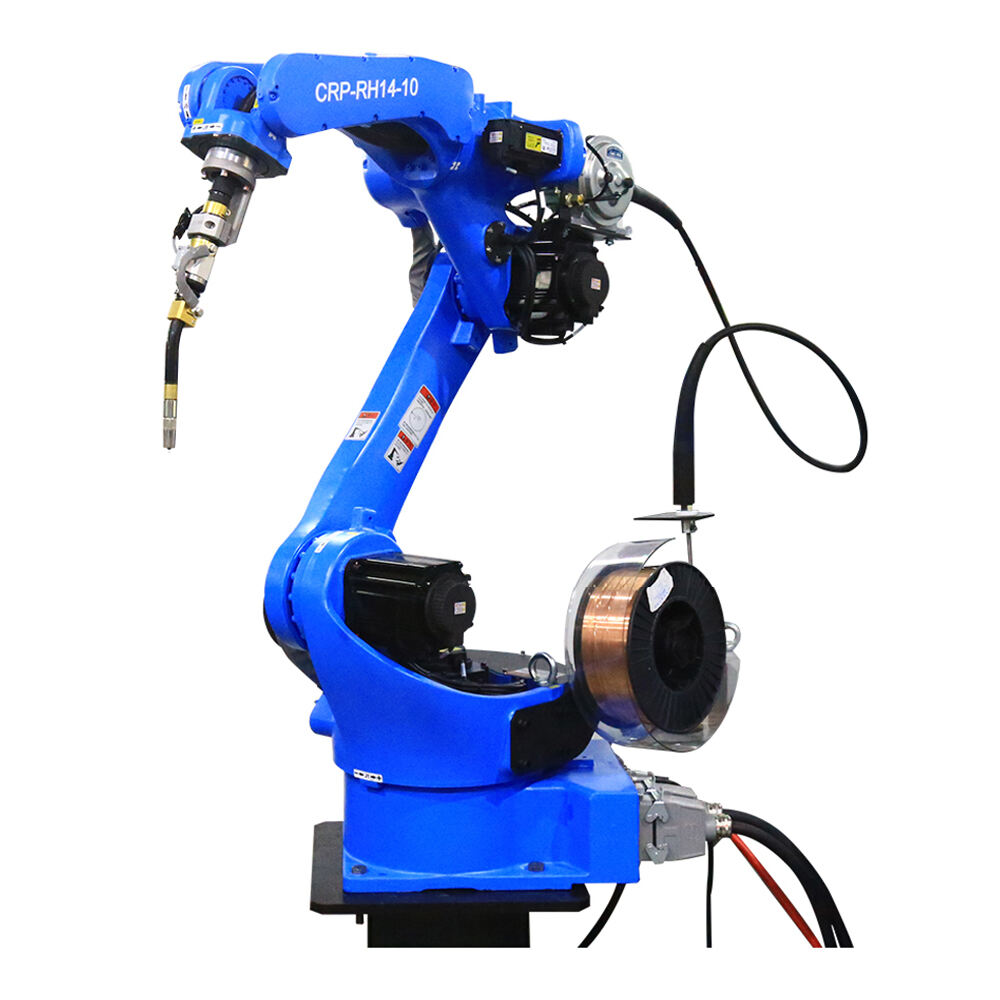

For large scale projects, our multi-function welding robots will help translate design into reality. With the ability to interface with virtually almost any robotic arc welding system, our multi-function welding robots can easily be deployed in mass production environments with repeated design processes. It doesn’t matter the automaker, aerospace manufacturer or millions of manufacturers on broad, our robots are always their best choice.