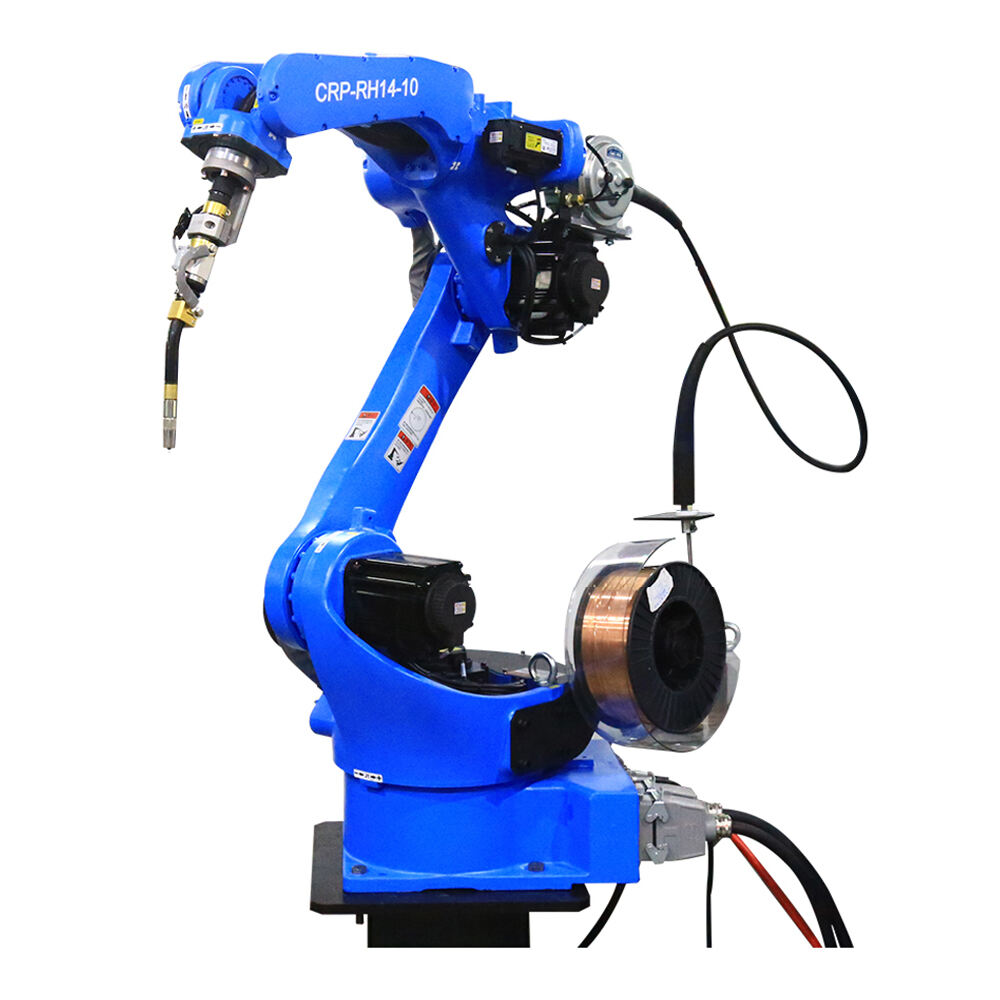

Robotic welding wire feeders are important devices in automated welding systems since they are responsible for welding quality and efficiency. Regular care is important to minimize problems like wire feed issues and jamming that can lead to poor quality welds and high costs. Adopting good practices maintenance calendars can rectify defects before they escalate into problems which allows for seamless processes in operations. Always, we at Rayman CNC consider that the equipment and machines should be operated effectively and therefore present resources and assistance that would improve on your productivity.