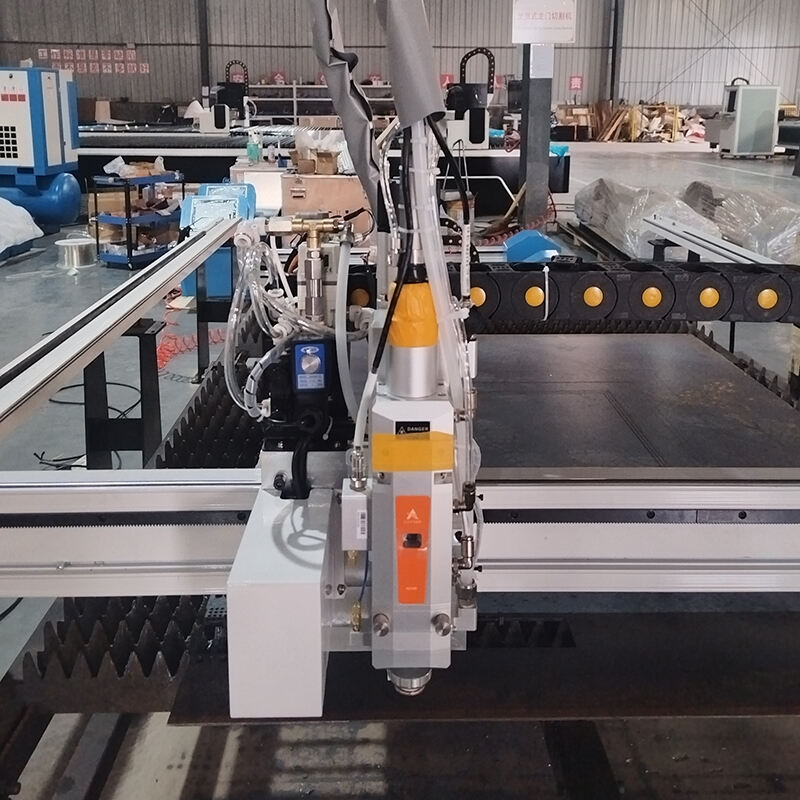

Pro fabricando metallo, secatio laser est processus qui mutavit quomodo fabricatores negotium agunt. Cum progressu technologiae, nostrae machinae secantes metalla laser usum fibrae opticae habent quae secant et operantur cum incredibili praecisione. Hae machinae per diversa metalla secant et etiam complexissima consilia sine ulla difficultate producere possunt. Negotium facilius fit per usum systematum technologicorum, quibus productio augetur, merces operariorum minuitur, et fides qualitatis asseritur. Cum provocationibus quas industriae experiuntur, Rayman CNC una est ex paucis societatibus quae innovationem habent quae ad necessitates actuales in celeriter mutabili foro globali requiritur.