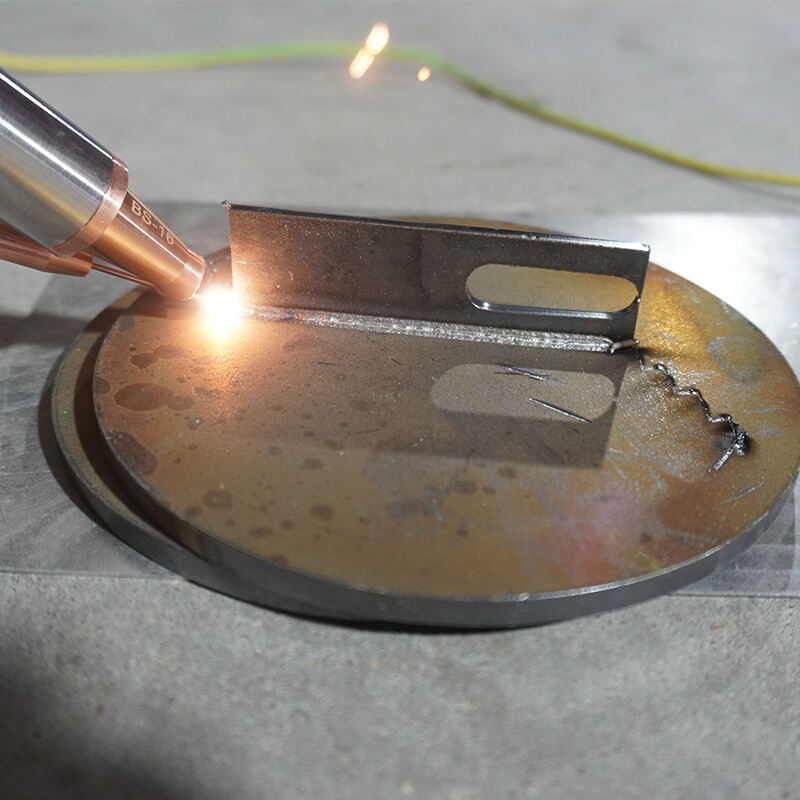

Maraming bagay ang umikot sa malinis na laser welding at ito ay posible dahil sa trifecta ng pagpapabuti na nagdadala ng pagbabago sa larangan ng teknolohiya ng welding. Tulad ng saklaw ng malinis na laser welding, gumagamit ito ng nakatutok na mga sinag ng laser at mga target upang makagawa ng matibay at malinis na mga teknika sa welding na nagreresulta sa pagbawas ng kabuuang mga apektadong lugar ng init. Lahat ay nakikinabang mula sa inobasyong ito, nakakatulong ito sa pagpapabuti ng proseso at kalidad ng welding habang pinoprotektahan din ang ekolohiya. Habang ang mga Welders at Industriya ay nagsusumikap na makasabay sa mga pag-unlad sa teknolohiya, ito mismo ang inaalok ng Rayman CNC, habang ang demand para sa mga welded na tampok na mas malinis, mas mabilis at mas matalino ay nasa pataas na trajectory.