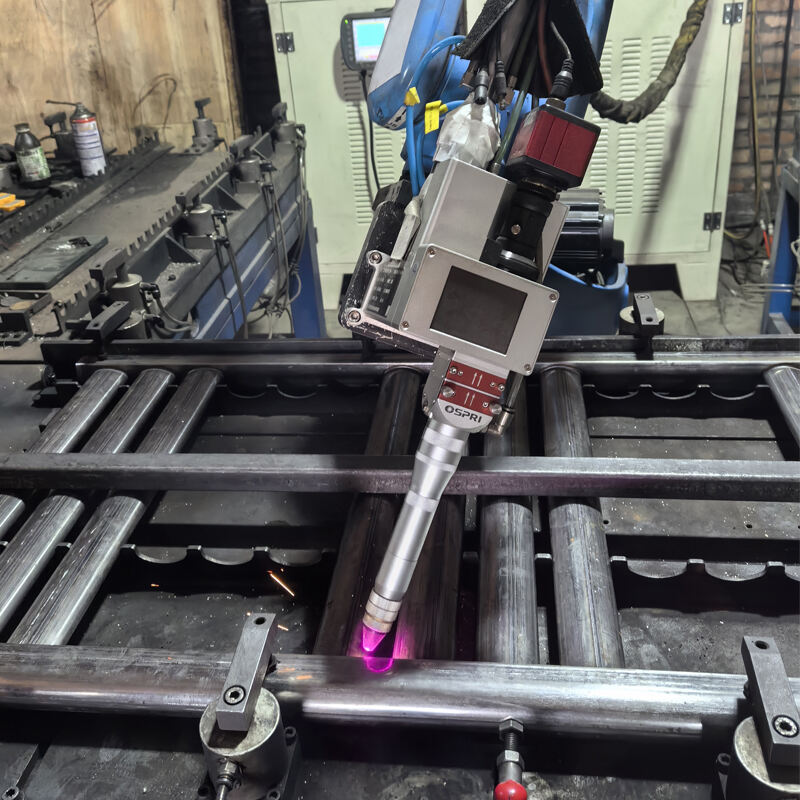

Rayman CNC is focused on a real-time control system of welding robots, taking it a step further in factory automation. The controls regulate welding parameters thus ensuring that best performance and quality is achieved through a set of system interaction. Such ability is paramount in industries that deal with precision and reliability in most of their operations inclusive of welding processes. For all sectors, it means that the client embraces new ideas aimed at better automation thus enhanced performance and reduced costs.